Highlights of the Series

The TF-P Series of Roller Compactors are envisaged to bridge the gap between increasing costs of imported equipment and available cheaper local solutions. The TF-P Series of Roller Compactors are designed and built to handle capacities from 300 g to 300 kg/hr. They are ideal for use in the Pharmaceutical, Nutraceutical and Chemical industries.

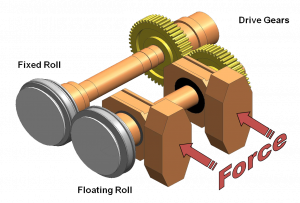

Constant Force Philosophy

The TF-P Series Roller Compactors are designed with Constant Force philosophy, where the Floating Roll is under a constant force imparted by a Power pack. This ensures that during compaction, the force on the powder across the rollers is maintained.

The result is UNIFORM HARDNESS & THICKNESS across the width of the flakes (including the edges), which in turn translates to UNIFORM DENSITY of the Granules.

Tapered Screw

As product is being fed into the compaction zone through the tapered screw feeding system, the powder is pre-compacted thereby exerting higher pressure and ensuring consistent feeding and compaction.Further the entrapped air is forced out along the side walls of the product hopper.

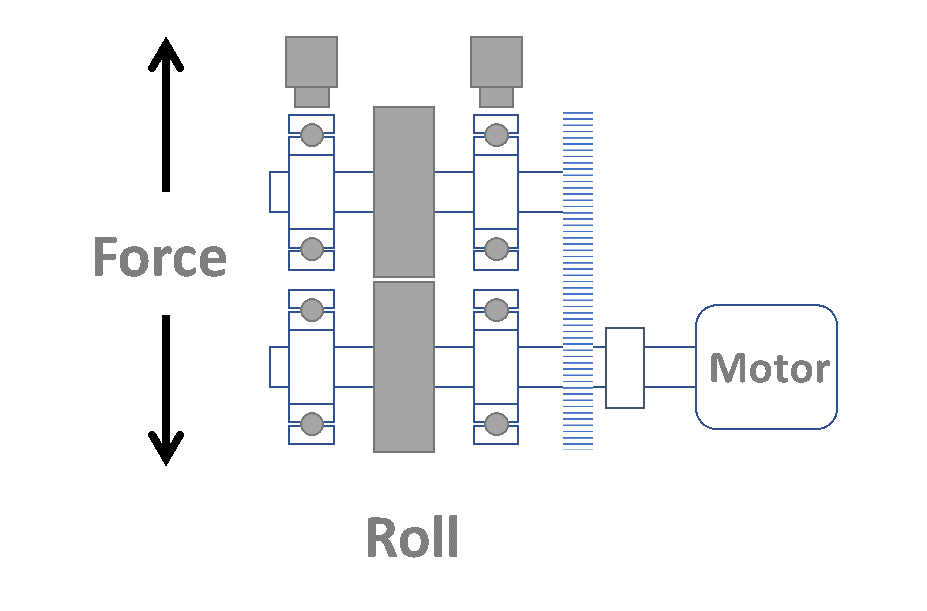

Dual Mounted Rolls

As the rolls are held from both sides, the gap between the two roll faces are always maintained parallel. This results in production of uniform flakes irrespective of the infeed powder condition.

TF – 3012P

The TF-3012P is suitable for medium to commercial scale production batch, optimal for granulating raw materials which are unstable in water or solvent, and are vulnerable to heat deformation.

[sp_easyaccordion id="2593"]

TF-208P

The TF-208P is a self-contained, easily operated roll compaction system built for dry granulation processes. Designed to handle up to 200 kg per hour, the machine is suitable for medium and high production scale.

[sp_easyaccordion id="2595"]

TF-MINI/P

Compaction can be determined with a minimum of 100g of powder. The TF-MINI has excellent scalability and allows for quick replacement of rolls and screws and instant testing.

[sp_easyaccordion id="2596"]